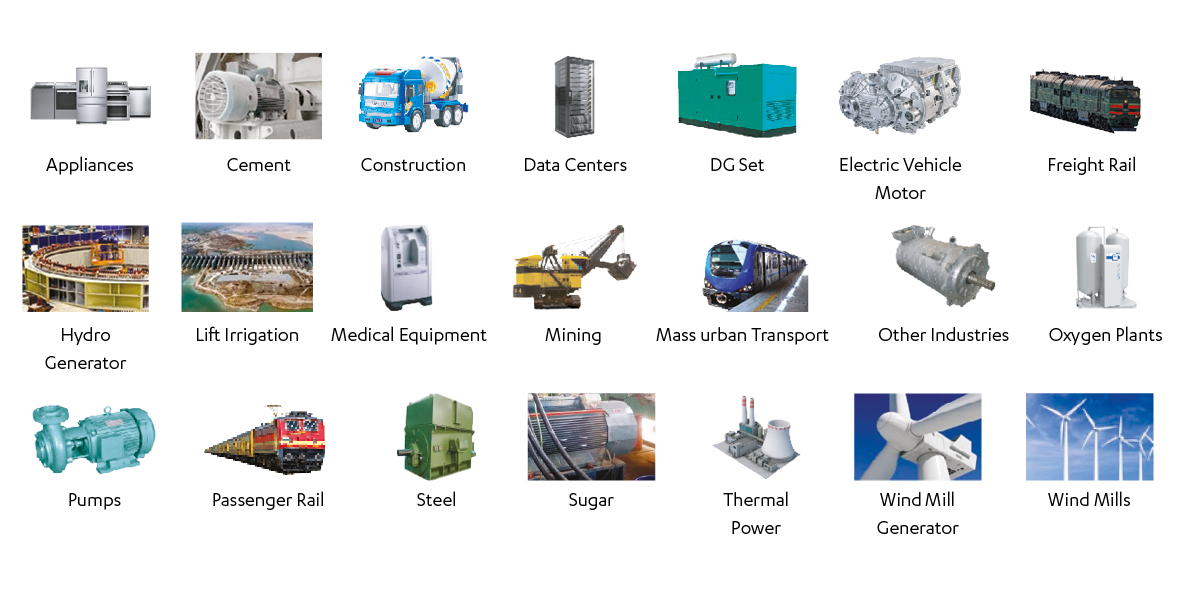

Our agility is derived from our proficiency to grasp evolving customer requirements. With a keen focus on understanding the unique needs of our clients, we aim to offer engineering excellence that forms an integral part of their supply chains and delivers immaculate value. It drives us to build processes and products that facilitate change, create one-of-its-kind products that lend us a competitive edge.

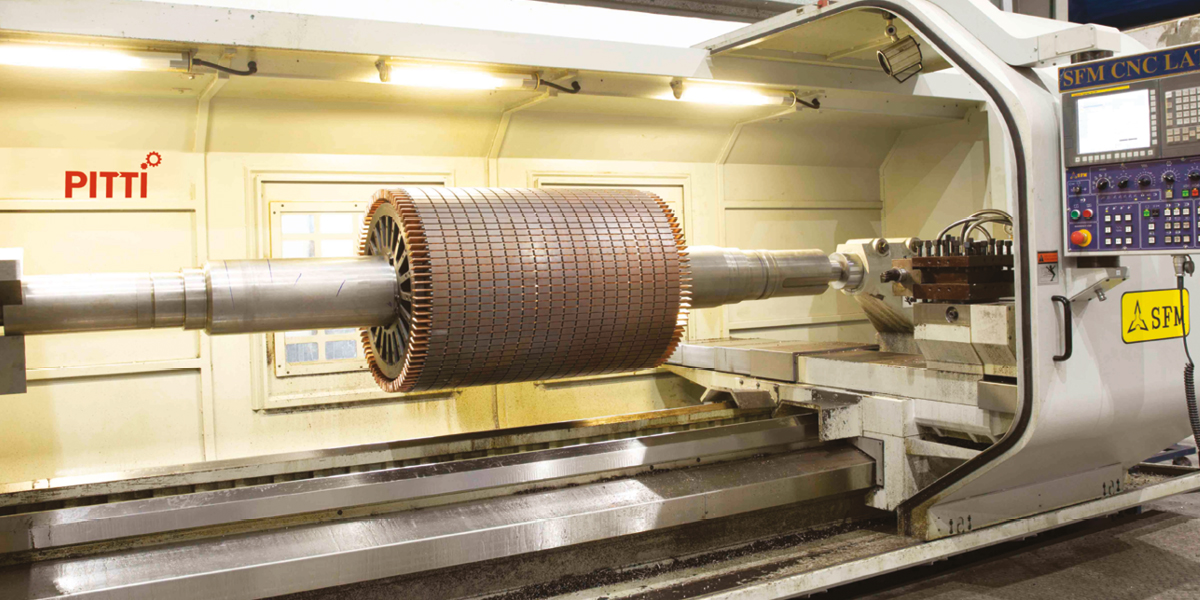

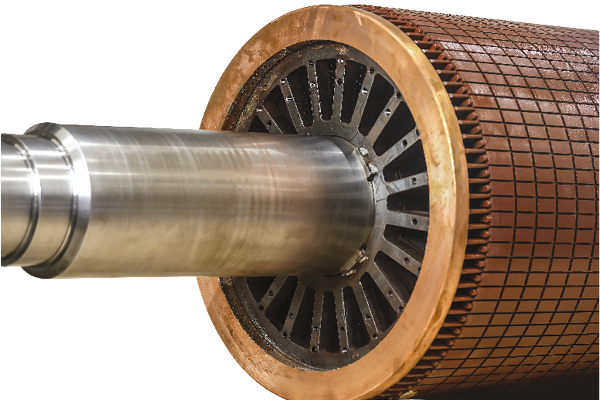

For years, we have steadily improved our manufacturing capabilities, introduced advanced technology and consistently fortified the entire value chain. In our relentless pursuit for excellence, we have strengthened every step of the organisational domain, from design and prototyping to production, packaging and logistics. With growing preference for precision engineered products, we are adopting methods to reduce redundant processes and aiming to sharpen our skills to align ourselves with emerging industry trends.

To support our growth objectives, we have relied on sustained capital expenditure to remain relevant and successfully tackle major shifts in industry preferences. At Pitti, we are enthusiastic about propagating agility across operations to make way for robust value creation and steer the organisation towards new growth paths.

We have also demonstrated our agility by efficiently responding to unexpected challenges. While the world remained in the throes of an unfathomable crisis in the year gone by, our resilience, perseverance and dedication empowered us to tide through tough times without a significant impact on financial performance.